Dan-Air Engineering warrants a dedicated section of the Dan-Air Remembered website. Most people don't give a second thought, when they are flying, that a tremendous amount of hard work, skill and dedication has gone into making the aircraft safe. The company did an excellent job, maintaining a fleet of upwards of 60 aircraft that were in the Dan-Air fleet. They were also responsible for the fleets of other airlines including Air Europe, Laker, and British Caledonian who have all made use of their engineering facilities. In addition Dan-Air Engineering maintained aircraft belonging to Sultans, Presidents and foreign Royal Family members. Please enjoy the story.

A New Maintenance Base

Following Dan-Air's acquisition of three Avro Yorks in 1954, the airline selected Lasham Airfield, a former Royal Air Force World War II airfield near the northeast Hampshire town of Basingstoke, as its maintenance base due to the ample availability of hangar space. Meredith Air Transport, whose operation at Southend Dan-Air had taken over at the time of its formation, lacked adequate maintenance facilities at that airport. When the fledgling airline moved its operating base to Blackbushe in 1955, it continued to face a shortage of adequate maintenance facilities as Airwork, Britavia, Eagle, Silver City and Westminster Airways, whose presence at the airport predated Dan-Air's, had already occupied most of the available hangar space. Blackbushe's lack of space resulted from its earlier use as a military airfield where no provision had been made for future commercial operations. The airport's biggest drawback was its location on both sides of the A30 along the Hampshire-Surrey county border, with the terminal and apron to the north and the maintenance area to the south, and taxiways as well as one of the runways crossing it. This arrangement necessitated frequent closures of the busy road on account of aircraft moving across it, thereby preventing the efficient use of both road and airport as well as ruling out any expansion. At the time, Lasham Airfield was in excellent condition, featuring a newly resurfaced runway and a large, empty hangar. The Air Ministry had decided to upgrade the airfield following the end of the Berlin Airlift in preparation for further Cold War tensions. Eventually, Davies and Newman, the parent company of both the airline and its new engineering division, managed to negotiate a 21-year lease of the airfield's maintenance facilities with the Air Ministry.

With the addition of the Ambassador, Dan Air required the workshop overhaul facility had to be expanded to handle hydraulic, pneumatic avionics, power plant builds and none destructive testing (NDT). After the Avro Yorks were retired, the airline's first pure-jet aircraft, the Comet, were brought into the fleet. At the same time, the engineering facility was increased to cope with the new aircraft, as well as DC4 and DC 7 aircraft. The Dove and Heron maintenance had to stop in favour of more DC3s introduced to handle an increased scheduled services commitment. A further increase in fleet size and the addition of a new jet aircraft in the BAC 1-11 in 1969 led to the need for a further expansion in hanger capacity.

Major Expansion In The 1970s And 1980s

A new hanger was commissioned in 1969 and was completed in 1970. The new hanger was 150 feet by 160 feet. The new hanger was 45 feet high and was able to handle the next maintainence project, the introduction of the Boeing 707 and the HS 748. Dan-Air's purchase of a pair of de Havilland Comet series 4 jetliners from British Overseas Airways Corporation (BOAC) saw these aircraft ferried from BOAC's Heathrow base to Lasham during the early summer of that year for conversion by Dan-Air Engineering from a 74-seat, low-density, two-class long-haul scheduled configuration into a 99-seat, high-density, single-class short - to medium-haul inclusive tour (IT) layout. This conversion also involved structurally "reinforcing" the aircraft — including strengthening the cabin floor and the wing roots — as they were expected to perform many more takeoffs and landings after entering service with Dan-Air (compared with their original role at BOAC). Dan Air subsequently acquired, larger Comet series 4B and 4C aircraft, these too underwent similar structural modifications to enable them to carry up to 119 passengers before

Dan-Air's acquisition of the first two BAC One-Elevens from American Airlines necessitated a major modification programme at Lasham before these aircraft could join the UK civil aircraft register as these were 400 series models that had been built to comply with US airworthiness requirements, which differed in several important aspects from the UK's airworthiness requirements. The introduction of Dan-Air's first American-built jet aircraft, an ex-Pan Am Boeing 707 320 series "Intercontinental", in 1971 eventually led to Dan-Air Engineering being granted "FAA Repair Station" status. This meant that it could perform maintenance, repair and overhaul (MRO) tasks on aircraft that were on the US civil aircraft register and/or were governed by US airworthiness standards. Dan-Air's decision to become the first British operator of the Boeing 727 resulted in the purchase of three 100 series examples from Japan Airlines (JAL) in 1972. As these aircraft lacked high frequency (HF) radios, they needed to be flown across the Pacific with two intermediate 24-hour stops at Wake Island and Honolulu (where the aircraft refuelled and waited for the overflight of the next scheduled Tokyo — Los Angeles 747 service to provide navigational assistance for the next stage of the onward journey until Los Angeles was reached). After reaching the US, they underwent an extensive modification programme at Boeing's Wichita plant in Kansas to comply with British Civil Airworthiness Requirements (BCAR). These modifications entailed the installation of and additional emergency door on each side of the rear fuselage and a full stall-protection system, including a stick pusher and stick shaker. Following their arrival in the UK at Dan-Air Engineering's Lasham base each aircraft was fitted with new galleys manufactured by Dan-Air Engineering together with 150 seats. The aircraft were also repainted at Lasham prior to their entry into service with Dan-Air in 1973.

Dan-Air Engineering had surplus capacity in the early seventies and was in a position to sign a contract with two UK airlines who operated the CL44, to undertake all their maintainence requirements, they also provided engineering for some American owned Boeing 727, based in the Mediterranean and Middle East. This successful venture into contract maintainence persuaded the company to further extend the facility, and in 1975 another 150 by 120 feet extension was built to handle the increased flow of aircraft, which had now increased to a fleet of 70 aircraft. Dan-Air's fleet stood at 49.

Left - G-BAEF in JAL colours with its UK registration. The new emergency doors are visible. The Aircraft was repainted in Dan Air colours shortly afterwards. Right G-AXCX BAC 1-11 in 1969

By the mid-1970s, Dan-Air Engineering's workforce had expanded to more than 800, the vast majority of whom were based at Lasham.

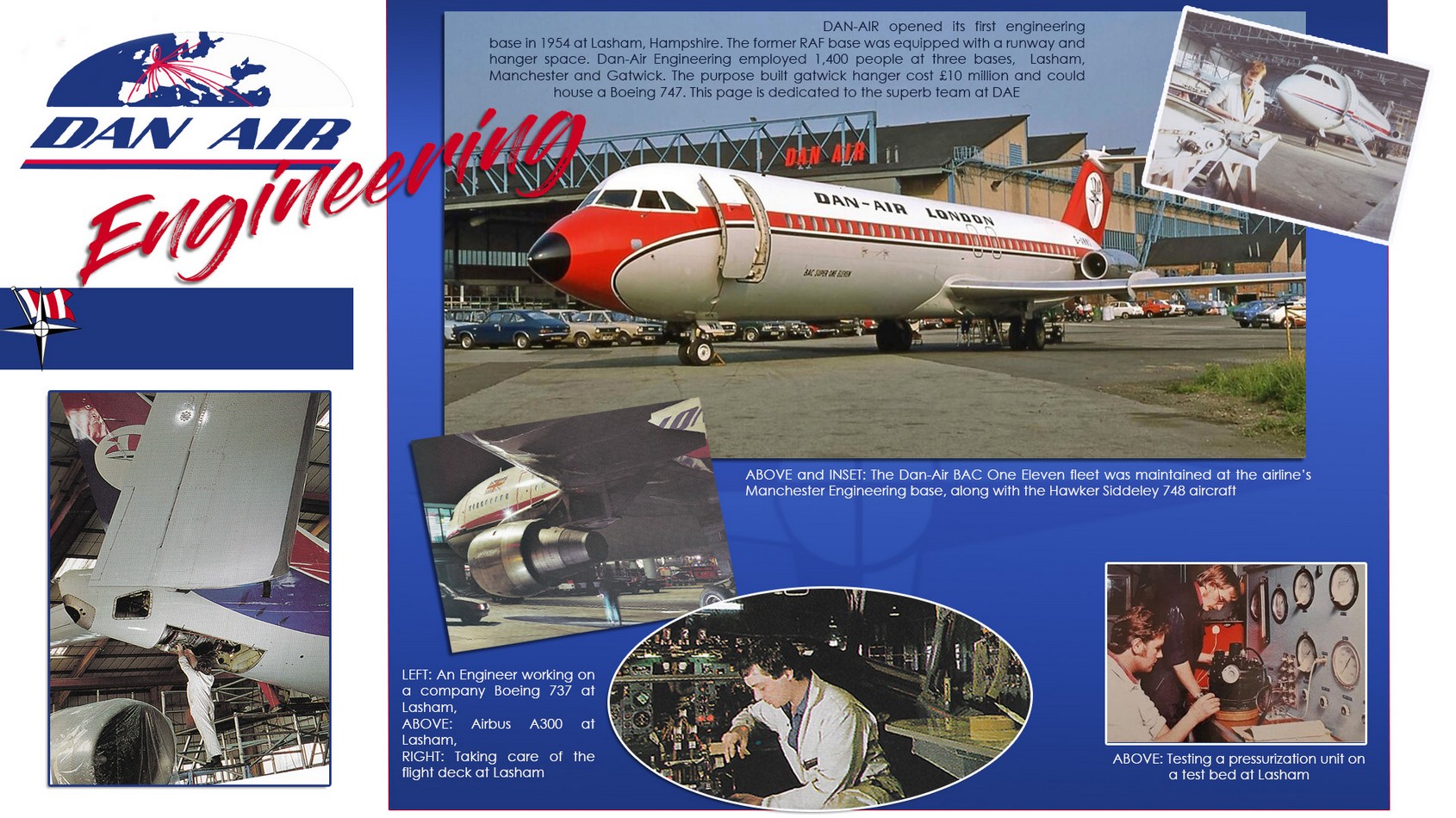

Dan-Air Engineering's second maintenance base at Manchester Airport in 1976. Dan-Air's thirty strong fleet of BAC One-Eleven and Hawker Siddeley 748 aircraft would be maintained at the new base. It also developed third-party de Havilland Canada Dash 7 and McDonnell Douglas MD-80 maintenance capabilities, as a result of which Lasham began to specialise in the maintenance of all Boeing narrow-bodied aircraft types. Eventually, Dan-Air Engineering became the second biggest employer at Manchester Airport, after the airport authority.

The Manchester base was soon in a position to offer third party maintainence to other operators. Soon the BAC 1-11 aircraft of British Island Airways, Cyprus Airways, British Caledonian, as well as others were being maintained at Manchester. Dan-Air's own introduction of the Viscount aircraft would mean that they too would head for Manchester for maintainence. Two other airlines contracted Dan-Air Engineering to carry out maintainence on their Viscount fleet.

Between visits to either Manchester or Lasham, the fleet was looked after by Dan-Air's Line Engineers who were based at Gatwick, Aberdeen and most UK airports where the company flew. There was also a team based at Tegal in West Berlin.

Dan-Air had its entire 17-strong One-Eleven fleet hush-kitted at Dan-Air Engineering's Manchester base by the end of 1985. By the late-1980s, Dan-Air Engineering's total workforce had almost doubled to 1,500. New aircraft evaluated in the late 1960s included the McDonnell Douglas DC8. The Boeing 707 was the chosen type, Dan Air Engineering was certified to carry out major C Check engineering on both ranges. As well as many other types. They were licensed with the UK Civil Aviation Authority and the United States FAA. Major contracts from UK airlines came in the 1970s British Caledonian, Laker, British Island Airways and by the end of the decade Air Europe entrusted Dan Air Engineering

Hangers at Lasham (left) Manchester (right)

Further Expansion In The Late 1980s

On 28 February 1989 Dan-Air Engineering opened its third base at London Gatwick, Dan-Air's main operating base since 1960. At that time Dan-Air Engineering maintained over 100 aircraft, including Dan-Air's 50 plus fleet. The new Gatwick maintenance base featured Dan-Air Engineering's first and only wide-body-capable hangar, located at the airport's northwest side. The largest aircraft that could be serviced was the Boeing 747 400 series. HRH Princess Alexandra conducted the official opening ceremony for Dan-Air Engineering's new hangar at Gatwick Airport on 18 April 1989. The Gatwick hangar could handle all Western-built wide-bodied aircraft — including the Boeing 747, then the world's largest wide-bodied airliner in commercial airline service. Davies and Newman's decision to establish a new, wide-body-capable maintenance facility operated by Dan-Air Engineering at airline subsidiary Dan-Air's Gatwick base was taken in response to the following events:

Gatwick had experienced rapid growth since the late-1970s, with an increasing number of movements at the airport accounted for by wide-bodied aircraft, including those operated by US carriers on transatlantic scheduled services. The collapse of Laker Airways, Gatwick's largest resident operator of wide-bodied equipment since the early-70s, during the early part of the 1980s had led to the concentration of all wide-body-capable hangarage and associated maintenance capabilities in the hands of British Caledonian. British Caledonian was the airport's largest resident operator and its leading scheduled airline, which also happened to be the main transatlantic competitor of most of the Gatwick-based US carriers. The result was a shortage of independently owned/operated, wide-body-capable maintenance facilities at Gatwick. (The unease of these US carriers at having to rely on wide-body-capable maintenance facilities controlled by their main transatlantic competitor for their Gatwick operations grew when British Airways, a far bigger as well as operationally and financially stronger airline than British Caledonian, inherited these facilities as a result of its takeover of that airline during the latter part of the 1980s.)

Since the beginning of the 1980s Dan-Air itself had been looking at introducing aircraft that were more advanced and had a greater seating capacity than the Boeing 727-200 Advanced, the largest contemporary aircraft in the airline's fleet, to combat rising jet fuel prices and to make the best use of Gatwick's increasingly scarce early morning peak time slots. This led to the evaluation of the Boeing 757 and several other state-of-the-art, high-capacity narrow - and wide-bodied aircraft types. That evaluation process resulted in the introduction of a 336-seat ex-Hapag-Lloyd Airbus A300 B4 series wide-bodied aircraft into Dan-Air's fleet in 1986. This in turn necessitated putting in place the maintenance infrastructure to support the operation of the airline's first wide-bodied type at Gatwick. Gatwick's increasingly tight slot situation from the second half of the 1980s made frequent ferry flights to/from Lasham and Manchester to maintain Dan-Air's large, Gatwick-based narrow-bodied fleet less and less feasible as each movement accounted for by a non-revenue flight represented a lost commercial opportunity. The opening of Dan-Air Engineering's third maintenance base resulted in an increase in the engineering unit's total staffing level to over 1,600.

Airbus A300 G-BMNC at Dan Air Engineering's Gatwick Hanger.

Change Of Ownership

Dan-Air's growing financial problems from the second half of 1990 against the backdrop of a severe recession in the UK and a looming war in the Gulf led to a change in Davies and Newman's top management. The company asked for a usual loan and was refused by the bank, eventually a rescue package was put together giving the airline extra funding. One of the stipulations of the deal was that company Doctor David James was to head the board as chairman and to have full control over who was to join or leave the board. Several aviation experts who had served on the board were replaced by business men from other industry backgrounds. They failed to see that Dan Air Engineering was asset rich. The new board decided to change the airline's strategic direction with profound implications for the engineering unit's future. Their decision to focus Dan-Air's future activities on the provision of fully fledged scheduled services on high-profile domestic and international European trunk routes from the airline's Gatwick base with a fleet of brand-new Boeing 737 300/400 series and BAe 146 300 series/Avro RJ115 jets meant that Dan-Air Engineering's capacity exceeded its sister airline's maintenance requirements by 45%. At the same time, Dan-Air Engineering was facing growing competition in the global third-party MRO market from rival specialist providers with far greater economies of scale, considerably lower labour costs and much more powerful parent organisations in places such as China, the Middle East and the Republic of Ireland. As a result, Davies and Newman was no longer in a position to fund the competing investment requirements of both its airline and engineering subsidiaries from its own, limited financial resources. It therefore decided to focus all its resources on Dan-Air and to sell off Dan-Air Engineering to a major, specialist MRO provider with the expertise and resources to continue investing in it. In the event, Davies and Newman sold Dan-Air Engineering to FLS Aerospace, a major specialist MRO provider in the UK and Ireland with bases at Stansted, Manchester and Dublin, for £27.5 million on February 28, 1991.The sale of Dan-Air Engineering to FLS Aerospace resulted in a reduction in employment at the remaining Davies and Newman group companies from 4,000 to 2,500, almost all of whom continued to be employed at Dan-Air. The Gatwick hanger had cost £5.5 million as had the latest testing equipment a well as engineering equipment, machinery, and spares. Similar plant was located in Manchester and at Lasham. The sale cleared Dan - Air's debts. Shortly afterwards it was discovered that the value of the spares and plant held at the engineering units were worth £20,000,000 alone. the sale was considered by many to be a mistake, in part because Dan - Air aircraft would still need maintenance and alternatives could have been made to downsize. David James James announced that this was a "Happy Occasion, where both parties achieve something of major benefit" He claimed that the sale would open the way for the new Davies and Newman board to concentrate on the development in future strategy. Was the new board actually saying that an airline engineering company that gave priority to it's own aircraft, had worked with the airline since 1954, serviced the aircraft of other airlines was a hindrance to the airline? That somehow it was too difficult to manage? That it didn't want to have this company running side by side with it? In any case. The 1,600 employees would have to wait to hear their fate. Dan - Air Engineering Ltd was respected the World over. It maintained the aircraft of Royal Families and VIP transport. It was a success in it's own right. The threats from overseas with competition were real. But with the right strategy there was scope for making the company a success. The sale happened quickly. It could be seen as asset stripping. In any event the company had been sold

Following Dan-Air Engineering's sale, Dan-Air awarded FLS Aerospace the contract for the maintenance of its fleet. (FLS Aerospace's loss of the Dan-Air maintenance contract as a result of the airline's takeover by British Airways in 1992 led to the decommissioning and mothballing of the hangars it had acquired from Dan-Air Engineering at Gatwick and Lasham. The Gatwick hangar was subsequently brought back into service in the late-1990s following British Airways's decision to make the airport a major hub. It was decommissioned once more as a consequence of British Airways' subsequent decision to de-hub Gatwick, following the adoption of a new corporate strategy aimed at restructuring the airline's loss-making operation at the airport in the aftermath of recording its first-ever full-year loss since privatisation in 2000. Most recently, on 1 August 2006, Virgin Atlantic took over this hangar to provide an in-house maintenance capability for its growing Boeing 747-400 fleet at Gatwick as well as to support sister airline Virgin Nigeria's daily Airbus A340 operation from/to Lagos at the airport. Meanwhile, FLS Aerospace itself was acquired by SR Technics, the former maintenance arm of defunct Swissair, in 2004. Towards the end of 2006, SR Technics in turn was jointly taken over by the governments of Abu Dhabi and Dubai (through Mubadala and Dubai Aerospace Enterprise, respectively), who then incorporated it into their nascent MRO venture. The former Dan-Air Engineering maintenance base at Lasham was acquired by ATC Lasham, a Boeing MRO specialist, in 1995.

Workshops

The following workshops could be found at Dan - Air Engineering

- Battery Shop

- Brake Shop

- Components Shop

- Components Painting Shop

- Electrical Shop

- Flight Data Recording Shop

- Fibreglass Shop

- Hydraulics Shop

- Instrument Shop

- Machine Shop

- Wheel / Tyre Shop

- NDT Shop

- Oxygen Shop

- Power Plant Shop

- Pressure Shop

- Radio Shop

- Safety Equipment Shop

- Sheet Metal Shop

- Thrust Reverser Shop

- Upholstery Shop

- Welding Shop

Facts Of Interest

- Dan-Air Engineering restored one of the Douglas Dakotas operated by Dan-Air as the airline's first aircraft, applying the contemporary livery and aircraft registration (G-AMSU). The aircraft, which was originally registered G-AMPP when in commercial airline service with Dan-Air, was on display at Lasham from 1971 until 1991.

- During the 1970s Dan-Air Engineering developed a comprehensive non-destructive testing (NDT) capability. (This assumed added significance following the loss of one of Dan-Air's Boeing 707 freighters during the second half of the 1970's due to metal fatigue, leading to the separation of the aircraft's horizontal stabiliser in mid-air.)

- During the early-1980s Dan-Air Engineering's Manchester base designed and installed a then unique cargo door in one of Dan-Air's Hawker Siddeley 748 turboprops that had specifically been acquired for this purpose. This enabled the aircraft — a series 2 HS 748 (registration G-BIUV) fitted with an 8 ft (2.4 m) by 8 ft (2.4 m) rear cargo door — to carry "outsize" cargoes, such as pipes and oil drilling equipment measuring up to 6 in (15 cm) in diameter and up to 40 ft (12 m) in length, which made it particularly suitable for oil industry support work.

- During the 1980s Dan-Air Engineering held the contract to maintain the Qatar Amiri Flight's Boeing 727-200 Advanced VIP aircraft fleet. The flight deck crew flying these aircraft were seconded from Dan-Air.

ENGINEERING GALLERY

DISCUSS THIS SUBJECT

3

reviews

Andy Frish

Saturday 15 Jan 2022

So many memories of both flying Dan Air (Comets G-APDJ and G-APDP in 1971) and regularly visits to Lasham during school lunch hours! The security guys at Lasham got to know us really well, I still have hundreds of slides of Comets in every state of repair, 707s G-AYSL and G-AZTG together at Lasham for the first time, Jal 727s being repainted etc etc etc. They were really happy days, we had a ball. Thank you Dan Air for the memories. I still have a brand new pair of white Dan Air Engineering overalls they gave me. Sort of makes me look like am aviatory Elvis! i need my TARDIS to go straight back there!

Dave Libby

Saturday 27 Jul 2019

First flew Dan-Air in September 1980 with my family from London Gatwick Airport to Malaga, Spain on a very nice vacation. (BAC Super One Eleven) great flight, excellent service!

Also flew to Inverness from London Heathrow Airport on BAC Super One Eleven and later the Boeing 737.

First class service, excellent flights, really nice meals on board, brilliant crews, the best!

Sweets on take off! Very nice!

Can only say, Dan-Air were a fantastic airline to fly on!

Sincerely,

Dave Libby,

IATA/UFTAA dip.

Also flew to Inverness from London Heathrow Airport on BAC Super One Eleven and later the Boeing 737.

First class service, excellent flights, really nice meals on board, brilliant crews, the best!

Sweets on take off! Very nice!

Can only say, Dan-Air were a fantastic airline to fly on!

Sincerely,

Dave Libby,

IATA/UFTAA dip.

Greg Romagnoli

Friday 26 Jul 2019

Well when once asked by a Big Banana Tech Director of another airline Engineering Company that they had built a hangar at Manchester ..What if we cannot get the tail of our latest fleet addition into the hangar? I

suggested

1 cut a template in the roof

2 let the tyres down and ask the engineers to SIT on the wings..or

3 Dig a well for the tyres to enable it to duck under the hangar doors.

I am not an Engineer but Dan Air Engineering taught me a lot. Sadly sold as a massivegoing concern IMO

suggested

1 cut a template in the roof

2 let the tyres down and ask the engineers to SIT on the wings..or

3 Dig a well for the tyres to enable it to duck under the hangar doors.

I am not an Engineer but Dan Air Engineering taught me a lot. Sadly sold as a massivegoing concern IMO